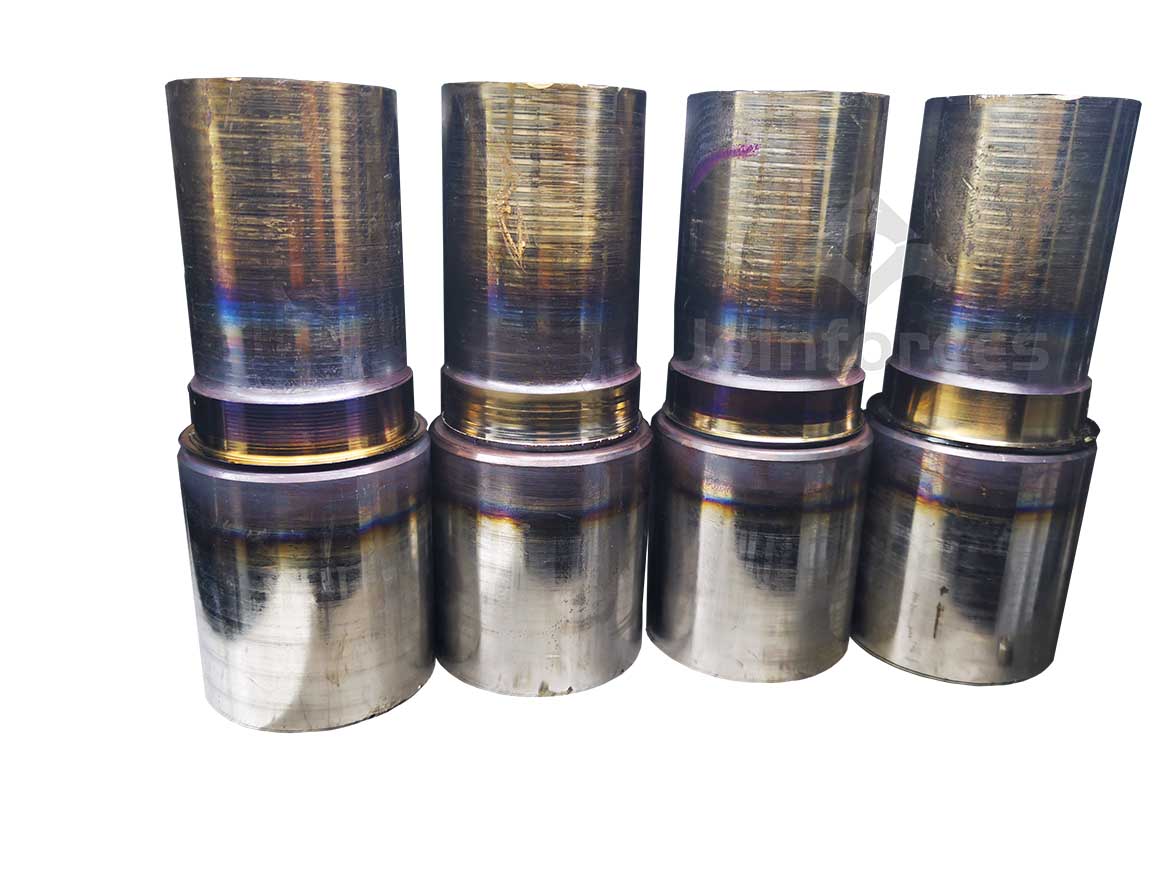

Friction welding partsOEM service

OEM friction welding service, parts processing service by using friction welding technology process.

Relying on its own R&D and production capacity and excellent accumulation of friction welding technology, Zhonghe Machinery Technology can provide customers with satisfactory OEM services.

Zhonghe Machinery Workshop has 6 friction welding machines to undertake OEM services; 1 set of all-electric phase friction welding machine, 1 set of 3/12/30/63/100 tons of equipment; available for pre-welding feasibility study, product proofing, welding Post-mechanical performance testing and post-weld heat treatment services.

Zhonghe Machinery Technology can realize the combined welding of various materials, and can provide more extended options on top of the basic functions, including single/double head drive, phase angle control, automatic flanging removal device, fully automatic robot on/off Cutting solutions and more personalized function customization.

Zhonghe Machinery Technology can realize the combined welding of various materials. The OEM friction welding processing capability of Zhonghe Machinery is most representative of bimetal welding, steel-aluminum, copper-aluminum; copper-steel, nickel-based alloy steel; stainless steel, etc.

Zhonghe Machinery's OEM top-end processing capability is most representative of bimetallic welding, which is often called steel-aluminum joint welding

Among them, the most representative steel-aluminum joints are mainly used for the transition connection between stainless steel pipes and aluminum pipes, and are mainly used for air-separated cold boxes; because the pipe connections in the cold box are not allowed to leak, they cannot be connected by flanges, only Welding can be used, but stainless steel and aluminum cannot be connected by ordinary welding technology, so steel-aluminum joints are needed for transition in such special requirement situation; at present, the steel-aluminum joints produced by Zhonghe Machinery mainly use friction welding technology, which has reached the leading level in China.

More OEM service products of Zhonghe Machinery Technology (Dalian) Co., Ltd. include bimetal welding (steel-aluminum joint welding)

Covers the following categories:

1 Automotive industry

2 petroleum machinery

3 bi-metal (steel-aluminum joint)

4 Aviation industry

5 military products

6 conventional industries

Quality control at whole process :

1 Machining processes when required

2 For further protection With certain machines and applications, the resulting welding flash can be removed automatically.

3 We do necessary heat treatment – Before and after welding

4 Cleaning to certain components in our machine in order to remove grease/oils and other possible impurities .

5 Checking the final parts physical data

6 Making assortment for the welded parts in reasonable sequence